SIGNIFICANTLY IMPROVE THE THERMAL PERFORMANCE OF YOUR WALLS with Bonded Bead Cavity Wall Insulation

KOREFill Bonded Cavity Wall Insulation is a System of installing Expanded Polystyrene Insulation beads into the cavity of New or Existing Buildings. Heat Loss from the walls can be reduced by up to 35%.

What is KOREFill Bonded Bead Cavity Wall Insulation and How is it Installed?

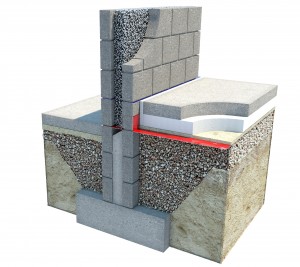

KOREFill Bonded Bead Cavity Wall Insulation is loose Silver Expanded Polystyrene Insulation (EPS) that is pumped into the cavity with a water based bonding agent. Once pumped into the cavity the bead solidifies to form an insulated mass.

To install the product properly the installation team follows a strict drilling pattern to ensure all areas of the cavity are completely filled. In new buildings the holes are drilled from the inside, in existing buildings the drill holes are drilled from the outside. The Breffni Insulation Installer will fill the drill holes completely and match the finish to the existing house.

The KOREFill Bonded Bead Cavity Wall Insulation System is completely certifed by the Irish Agrement Board and NSAI and the Breffni Insulation team is fully trained and certified to install the system.

Benefits of KOREFill Bonded Bead Cavity Wall Insulation System

U-values Options

New Builds: The U-value of KOREFill is only limited by the width of the cavity. Wall Type - 19mm external render on 100/100/100 block cavity wall (100mm clear cavity) with 12.5mm internal plasterboard will achieve a U-value of 0.31 W/m²K while a 150mm cavity will achieve a U-value of 0.21W/m²K.

Existing Builds: Where a home has existing insulation in the cavity, pumping the remainder of the cavity with Bonded Bead will significantly improve the thermal performance of the wall. U-value calculations for residual filling of partial fill cavity walls are dependent on the thickness and type of existing insulation and the width of the residual cavity.

KOREFill U‐value Summary Table

Element type: Cavity Wall Insulation

Calculation Method: I.S. EN ISO 6946, I.S. EN ISO 13370

|

Cavity Thickness (mm) |

U-Value W/m2K |

|

50 |

0.55 |

|

75 |

0.39 |

|

100 |

0.31 |

|

125 |

0.25 |

|

150 |

0.21 |

|

175 |

0.19 |

|

200 |

0.16 |

|

250 |

0.13 |

|

300 |

0.11 |

Wall: Render, Block, KOREFill Bonded Bead, Block, Plaster Skim

Reduced Thermal Bridging

A thermal bridge also known as a cold bridge occurs when there is a break or junction in the insulation material and accounts for 15% of the heat loss from the building. Bonded Bead significantly reduces the amount of thermal bridging in a home as the installation flows throughout the cavity. There are no breaks in the insulation material as so can often happen with insulation boards. When you choose to insulate your cavity walls with Bonded Bead you are employing an expert team whose only function is to insulate your walls 100%. The images below illustrate how the bead will fill all areas around the windows and doors and completely eliminate thermal bridging reducing cold spots on the walls.

Cavity Benefits

The installation of KOREFill does not hinder the function of the cavity. The natural matrix formed by the bead means that mositure that penetrates the outer leaf will not travel through the cavity to the inner leaf. The water by natural gravity will flow to the weep holes at the bottom of the cavity. The bead bond together in a honeycomb type formation allowing air to circulate and the cavity to breath.

Product Performance

The KOREFill System is rot-proof, water repellent, and durable and will not degrade over time. It will not prejudice the fire resistance properties of the wall. Once installed properly the KOREFill System will preform consistently for the life of the building.

Installation Benefits

KOREFill is only installed by fully trained and accredited installers. As a client you will not have to handle the product in any way. There is no site storage ot watse facilities required and we will bring our own specialised machinery and equipment. The installation process will take no more than a day (weather permitting).

Compliance with Building Regulations

KOREFill satisfies all necessary compliance issues regarding Building Regulations 1997 to 2012. Walls using KOREFILL Cavity Wall Insulation can meet the current U-value requirements in Full Fill Cavity Wall Insulation applications depending on the cavity width.

Site Storage

The KOREFill product does not need to be stored on site. The installer will arrive on site and the product is installed directly from the bead truck into the cavity. The client will not have to handle the product.

Site Machinery

The client does not need any specialist equipment or machinery on site. The Breffni installers are fully equipped with their own equipment.

No On–Site Waste

Your Breffni installer fills the cavity directly from the Bead truck and as such there is no material or packaging waste from the process. Any excess material remaining in the trailer once the fill is complete is removed by the Breffni Installer.

Fill Certainty

The installation equipment and technique is designed to guarantee that every meter squared of the wall is completely filled. The client can be one hundred percent certain that the walls of the building are completely filled with insulating material.

Time Saving

As the placement of the insulation is no longer the responsibility of the block layer the block walls will be finished much more quickly. Once the building is sealed from the elements the Breffni Installer will fill the cavity with the insulation.

Advantages of Bonded Bead Insulation

- Complies with part Lof the 1997 - 2012 Building Regulations.

- Offers a range of solutions to the 1997 - 2012 Building Regulations.

- 15-20% higher thermal performance than other systems.

- Constant density.

- Will not crack or settle.

- Will not transmit moisture.

- Cavity remains breathable.

- No site handling or storage.

- No bulk ordering, therefore cash flow advantage.

- Speed of installation